Jordi Cabana

Environmental Energy Technologies Division

Lawrence Berkeley National Laboratory

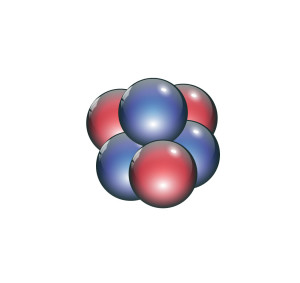

Battery systems based on lithium metal as the negative electrode could lead to gains in specific energy over Li-ion technologies. This is particularly the case in lithium sulfur (Li/S) and lithium/air (Li/air) batteries, which are increasingly gaining the attention of the scientific community. However, there are major technical obstacles which have thwarted this advancement for two decades. These include shape change and dendrite formation, which lead to short cycle lifes and, potentially, to short-circuits that severely compromise the safety of the device. This is in addition to side reactions with liquid electrolytes, which consume charge and generally lead to poorer performance with time.

A solution that has been long explored is that of using solid state electrolytes.1 More recently, battery systems with dual liquid-solid electrolytes have been proposed.2 In this case, a thin solid layer acts as a barrier layer between lithium and the liquid electrolyte. It must be ionically conductive and mechanically stable in order to prevent dendritic growth. A number of inorganic crystalline and amorphous phases are known to have suitable electrical properties.3 However, they pose the challenge of processing into a thin pinhole-free membrane. Further, most of them contain a transition metal, making them highly susceptible to reduction. During this presentation, strategies toward membranes based on ceramic conductors that can be used as protective layers for the lithium electrode will be discussed. Emphasis will be placed on sintering and composite architectures, as well as on the interfacial redox stability against metallic Li of the resulting structures. Electrochemical testing in Li symmetric cells will be used to evaluate the desired figures of merit.

Acknowledgements

This work was supported by the Assistant Secretary for Energy Efficiency and Renewable Energy, Office of Vehicle Technologies of the U.S. Department of Energy under Contract No. DE-AC02-05CH11231.

References:

J.W. Fergus, J. Power Sources 195 (2010) 4554.

M-Y Chu, S. Visco, L.C. De Jonghe, U.S. Patent No. 6402795, 2004.

P. Knauth, Solid State Ionics 180 (2010) 911.